The Advanced Manufacturing & Design Lab

From Prototype to Proof of Concept with State-of-the-Art Technology

SCROLL TO LEARN MORE

Driving Innovative

Science

With State-of-The-Art

Technology

What We Do:

The Advanced Manufacturing and Design Lab (AMDL) was created as a resource for our scientists and collaborators to build and explore new technologies that enhance data collection. Our lab uses state-of-the-art equipment to create novel scientific tools, controlling the process from idea to prototype to proof of concept.

AMDL plays an integral role in helping scientists overcome the vast limitations and challenges of conducting research both in the field and laboratory setting by engineering new, innovative designs for field equipment using the suite of cutting-edge manufacturing technology we have at our disposal.

Click the icons to explore:

Who We Are

Open Source Designs

Our lab is able to design everything from field equipment that enhances our ability to collect data with greater consistency to major laboratory renovations that unlocks new capabilities for advancing our research, as seen with our Experimental Reef Lab.

Our lab is able to simplify access and the sharing of designs. These designs are created and refined digitally until a prototype is ready to be printed or built.

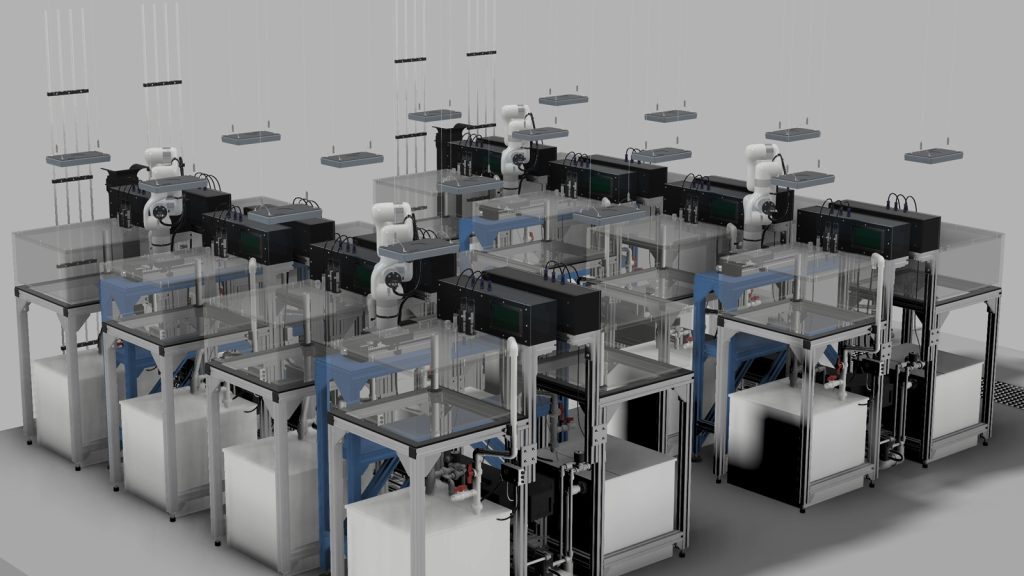

Creating Innovative Designs to Renovate Our Experimental Reef Lab (ERL)

AOML’s Experimental Reef Lab (ERL) located at the University of Miami was designed and built by AOML and the Cooperative Institute for Marine and Atmospheric Science (CIMAS). With 16 custom-built independent aquarium systems fully engineered using our Advanced Manufacturing and Design Lab (AMDL), we can manipulate temperature, light and pH to mirror projected ocean conditions and answer some of the most pressing questions about coral reef health in response to increasing environmental stressors.

As the Experimental Reef Lab undergoes major renovations, our team within the Advanced Manufacturing and Design Lab (AMDL) is using our open-source software capabilities to trouble-shoot and innovate a new, cutting-edge design for the aquarium system and its automated logging and control system that will bring in a new wave of coral research.

Modeling of “ERL2” Renovations Using Open-Source Designs

SAS and Additional Designs

Our lab is able to design everything from field equipment that enhances our ability to collect data with greater consistency to major laboratory renovations that unlocks new capabilities for advancing our research, as seen with our Experimental Reef Lab.

Our lab is able to simplify access and the sharing of designs. These designs are created and refined digitally until a prototype is ready to be printed or built.

SAS

For sampling water and analyzing changes in carbonate chemistry on coral reefs

SASe

For sampling eDNA in the water column

Automated Feeders

For transferring food into experimental tanks

Research Equipment Manufactured

The Subsurface Automated Sampler

The sub-surface automated dual water sampler was designed by researchers at NOAA’s Atlantic Oceanographic and Meteorological Laboratory and the University of Miami to help scientists study water chemistry on shallow reef habitats. It was also created to minimize some of the financial hurdles in marine research by serving as a low-cost open-source alternative to existing water samplers. Explore the sampler’s website, use it to guide you in building and using your own water samplers, embrace the maker movement and improve on our design. If you are a teacher, there are free lesson plans to download that include labs and activities related to science, technology, and engineering. Visit the site and learn how to build yours.

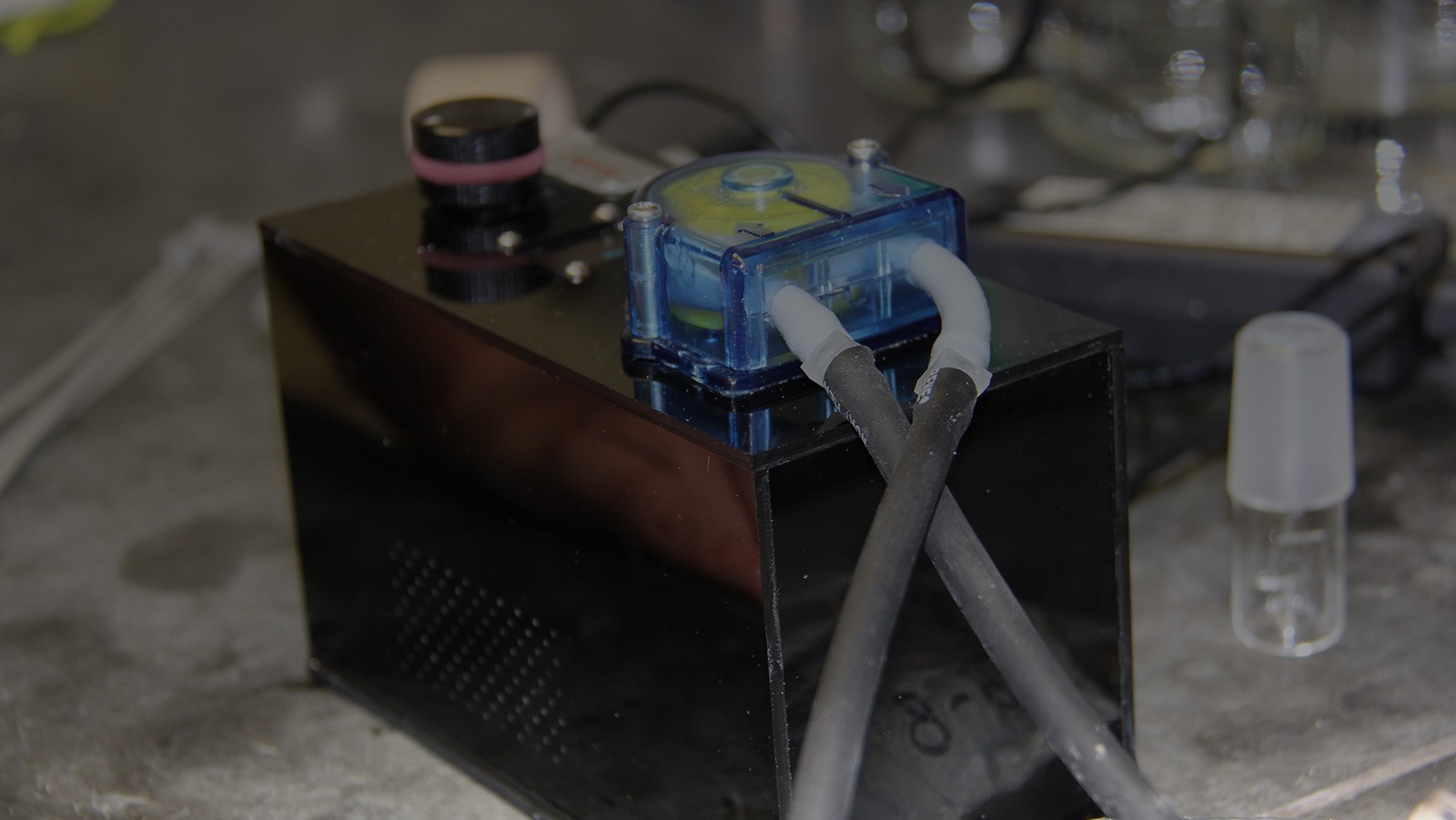

Fluid Transfer & Filtration

For Carbonate Chemistry Analysis

The Advanced Manufacturing and Design Lab at AOML has created a fluid transfer pump for low gas exchange transfer and filtration of precise and consistent volumes of seawater samples from sampling containers for carbonate chemistry analysis.

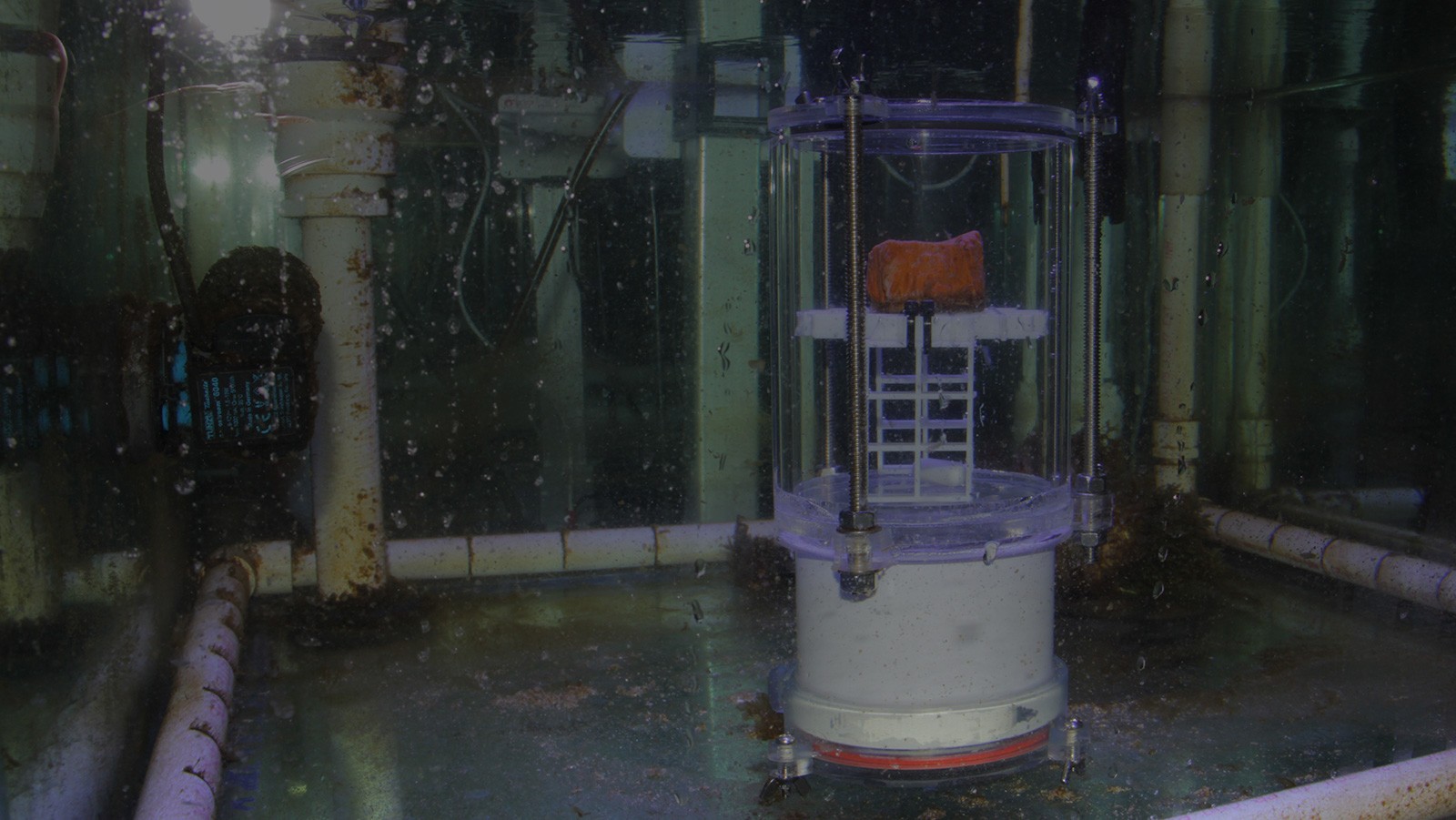

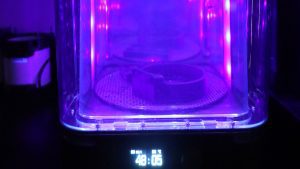

Submersible Incubation Chamber

For Respiration & Calcification Analysis

AOML scientists used the Advanced Manufacturing Lab to create a submersible incubation chamber for analyzing coral and sponge respiration and coral calcification in the lab.

Environmental DNA Sampler

For DNA Sampling in the Water Column

AOML scientists also created a sub-surface automated environmental DNA (eDNA) sampler for sampling eDNA in the water column. The low-cost open-source design will, similar to the SAS, help researchers sample eDNA at finer temporal and spatial scales for research and monitoring purposes.

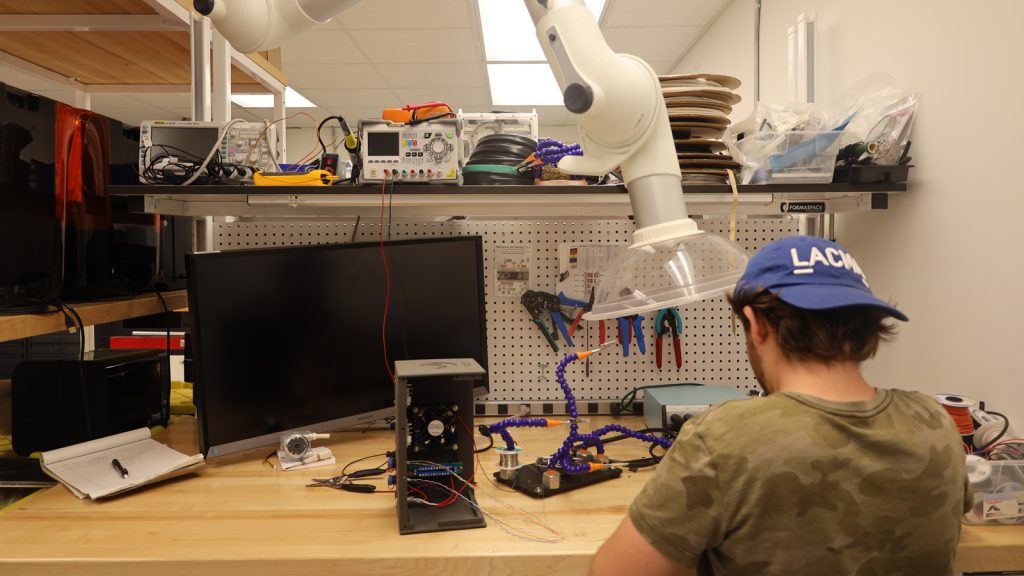

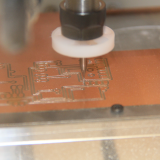

Our Manufacturing Capabilities

Our lab has embraced fused deposition modeling and stereolithography 3D printers, a 150W automated laser cutter, and an automated PCB milling machine.

These tools are available for home or commercial use, but bringing them together has given researchers at AOML the ability to quickly prototype and test new tools to assist in accomplishing our research goals by significantly reducing development lead time. The technology and tools created in the lab are used to collaborate with other institutions who are committed to engineering innovation in science and open-source technology.

The Process

3D Printing

Form2 Stereolithography (SLA) 3D Printer

SLA 3D printing uses a liquid resin cured by a UV laser to create watertight custom parts. This type of 3D printing is invaluable to us as marine researchers designing research tools for underwater deployment.

Form3 Low Force Stereolithography (LFS) 3D Printer:

LFS 3D printing uses a liquid resin cured by a laser focused by a specialized light processing unit for finer resolution waterproof prints with higher print consistency then the Form2. This system can print internal components at high resolution with minimal errors (e.g. internal threading or microfluidics).

Fuse 1 Printer 120V

The Fuse 1 Printer is capable of producing durable components for research equipment from nylon. With powder recovery performed in the final phase of printing, the Fuse 1 is efficient in creating the pieces as instructed during setup.

Post Printing Process:

The first step in post processing is an alcohol bath to remove excess resin. Dried parts are then put into a UV curing station to perform the final cure of all 3D printed parts after which the 3D printed parts will be stable and durable and ready for lab and field testing.

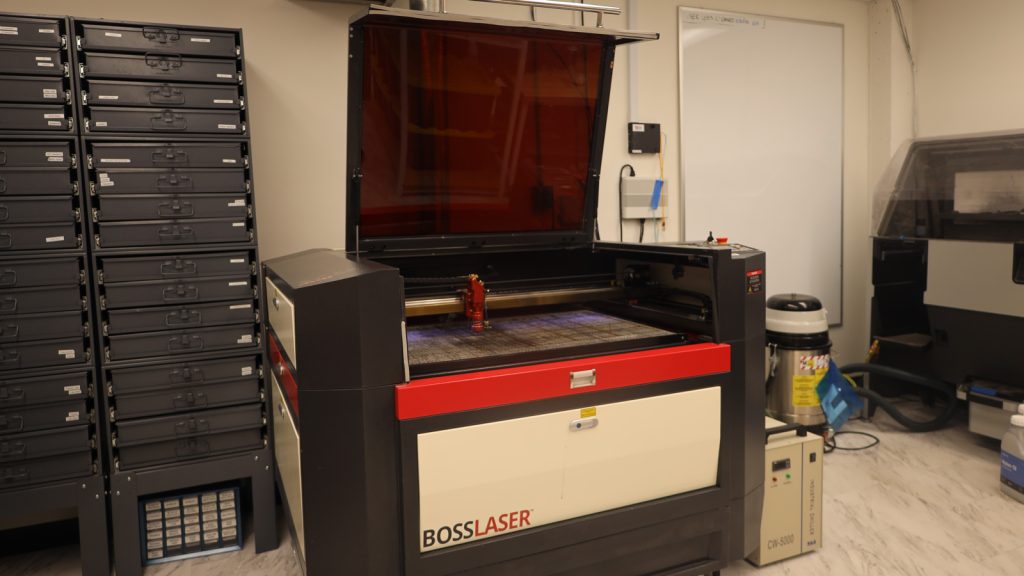

Boss Laser LS-2436 Laser Cutter/Etcher

The laser uses a 150W laser on a gantry system to cut and etch consistent high resolution designs from useful materials like acrylic, silicone, and rubber. The laser has been critical in cutting caps for submersible components, custom gaskets, and experimental pedestals for coral research.

Soldering Station

The soldering station includes soldering, heat gun, and desoldering vacuum capabilities for constructing circuitry and electric components for our projects, as well as in-house repair of damaged electric components in other marine research equipment.