Who We Are

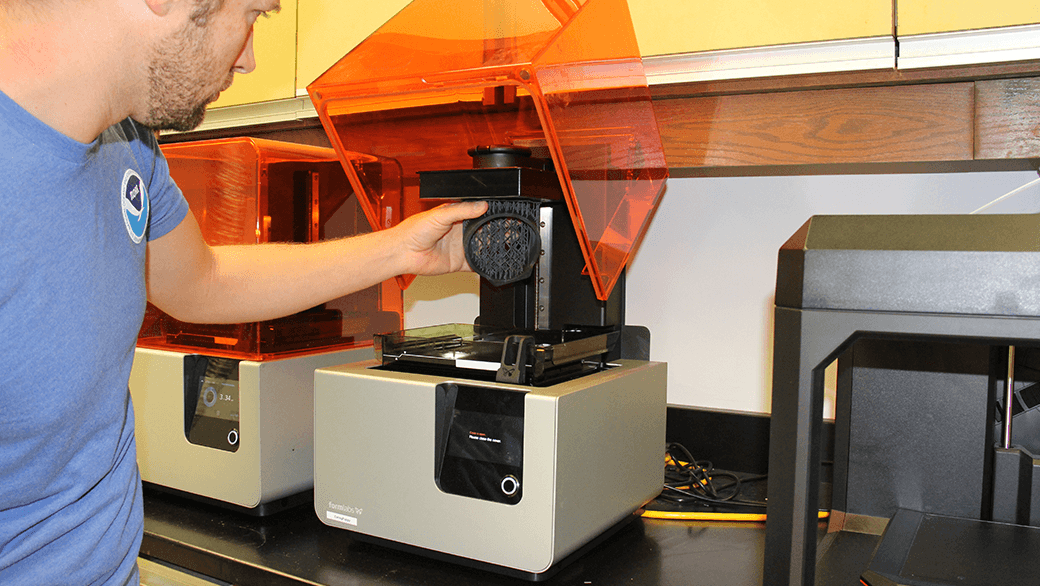

Dr. Ian Enochs is the Principal investigator for the Advanced Manufacturing and Design Lab with Nathan Formel as Project Manager. This lab was created to be a resource for scientists and collaborators to build and explore new technologies for enhancing research and data collection.

| Ian Enochs

Principal Investigator

| Nate Formel

Project Manager

What We Do

Research Projects

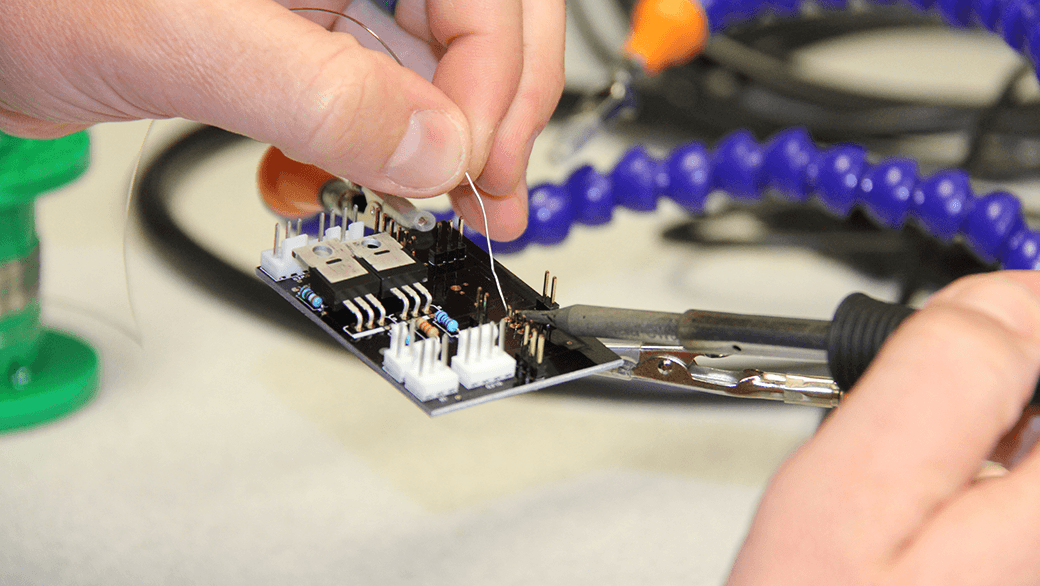

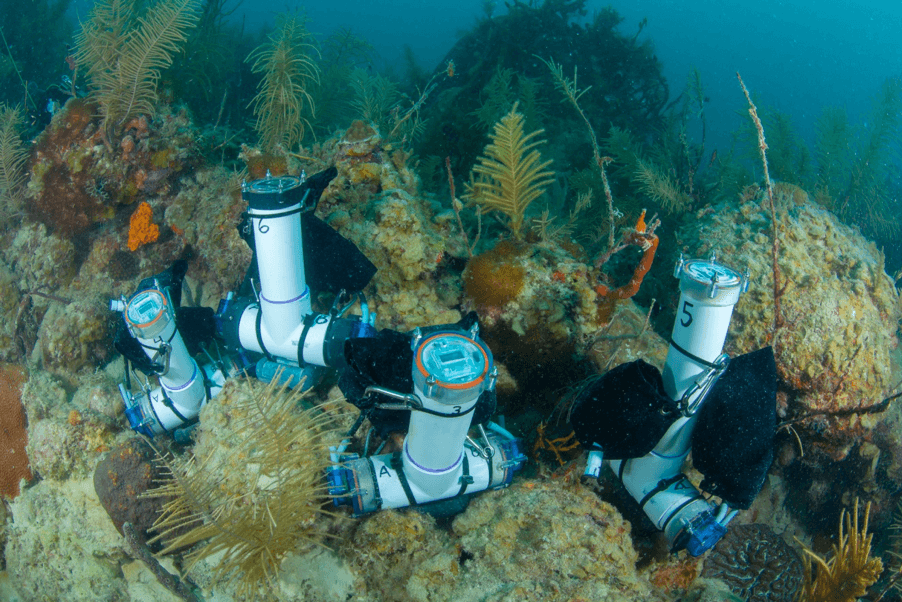

Subsurface Automated Sampler

The sub-surface automated dual water sampler was designed by researchers at NOAA’s Atlantic Oceanographic and Meteorological Laboratory and the University of Miami to help scientists study water chemistry on shallow reef habitats. It was also created to minimize some of the financial hurdles in marine research by serving as a low-cost open-source alternative to existing water samplers. Explore the sampler’s website, use it to guide you in building and using your own water samplers, embrace the maker movement and improve on our design. If you are a teacher, there are free lesson plans to download that include labs and activities related to science, technology, and engineering. Click the image to the below to visit the site and learn how to build yours.